A holistic approach that integrates Reorder Point management with broader business strategies is essential. Future innovations, such as blockchain and IoT, could further refine Reorder Point calculations by enhancing supply chain transparency and real-time tracking. Additionally, sustainability considerations may influence Reorder Point strategies to optimise not just for cost and service levels, but also for environmental impact. Ultimately, while the basic principle of Reorder Points remains constant, businesses that effectively leverage advanced approaches will gain a competitive edge.

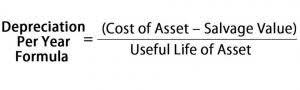

How Do You Calculate the Reorder Point Formula of a Product?

- Both ROP and EOQ play critical roles in effective inventory management, albeit utilized at different stages and for various facets of the inventory management process.

- The concept of Reorder Point (ROP) is actually pretty straightforward and can revolutionize the way you handle your business inventory.

- Regularly monitoring your inventory levels is crucial to recognize when you are nearing your reorder point.

- You also miss the opportunity to develop a deeper understanding of your supply chain.

- It aids in maintaining optimal stock levels, preventing stockouts, and making your operations more scalable and cost-effective.

Given the wide variety of products involved, as well as their complexity, firms will often employ multiple ROPs. In some cases, one person is designated as the principal while another is designated https://heallandgloww.com/plant-assets-what-are-they-examples-accounting/ as the alternate ROP. These positions are often reserved for senior members of the firm, such as its partners, officers, or directors. To see how the reorder point formula works in a practical setting, consider a small online bookstore that sells a popular novel. If you’ve been looking for fulfillment management software, you may have come across ShipStation. A well-known ecommerce fulfillment software, ShipStation is a great fit for small, single-brand sellers.

Using Inventory Management Software

For operational continuity, particularly in manufacturing, an effective ROP prevents disruptions caused by running out of what does rop mean in business materials or goods. Additionally, regularly adjusting ROP based on actual sales data improves demand forecasting and inventory planning. Lastly, optimising ROP contributes to better cash flow management by freeing up capital from excess stock, allowing businesses to invest in other critical areas. To refine Reorder Points and enhance inventory management, businesses can use several optimisation techniques. First, choose between continuous review of inventory levels, which offers responsiveness but is resource-intensive, and periodic review at fixed intervals.

Safety stock

This lack of a perpetual inventory system and a permanent way of updating the forecast made the calculation timing quite important. Now, all calculations are instantly performed whenever a change is made. The business should be tasked with re-determining the reorder point parameters for the product locations to be transitioned off the active planning track. If they are new to doing this, they may need some outside help from someone with a robust mathematical understanding of creating intelligent reorder points. Simplify your process with Intuendi and gear up for an efficient supply chain and inventory management system.

Reorder point calculation with different vendors

• Terms can be misleading in terms of safety stock and actual maximums. If you move from one type of MAX-MIN system to another but they define the MIN differently then you cannot just migrate your data. This may not seem obvious if everyone is using the language of MAX-MIN but is classic trap where words are used in different ways. However, with all other items the MAX is UNLIKELY to be equal to the ROP + ROQ as items may be issued between the time of reaching the MIN and the newly ordered items arriving. In fact, there is a logic that says that the MAX would never actually be achieved.

Getting accuracy in finding the reorder point in inventory control has the following advantages. The soft drinks are delivered in 2 days, but the snacks are delivered in 3 days. The company requires ten wooden pieces per day to produce ten dolls. But when the company does maximum production, it requires 14 packets per day. Safety stock is the number of materials or Bookkeeping vs. Accounting products stocked in the warehouse during unexpected emergencies.